How to Identify and Report Packaging & Bottle Defects

In this post, we are going to dive a bit deeper into packaging terminology. While it doesn’t happen often, manufacturing defects do occur and it’s extremely important to be able to report back exactly where the flaw is located. Defective packaging can affect the overall quality of the product that you have worked hard to put to market.

Here are a few examples of defects:

-

Cracks

-

Fractures

-

Stone or air bubbles in glass

-

Uneven or rough surface

Packaging defects may be categorized in the following manner:

-

Class A: Critical defect

-

Prevents a package from performing its intended function

-

Causes safety hazard in material handling

-

Example: Cracked glass bottle, missing liner

-

Class B: Major defect

-

Causes reduced functionality

-

Example: Heat seal too narrow

-

Class C: Minor defect

-

Affects appearance, but leaves functionality intact

-

Example: Stone or air bubbles in glass

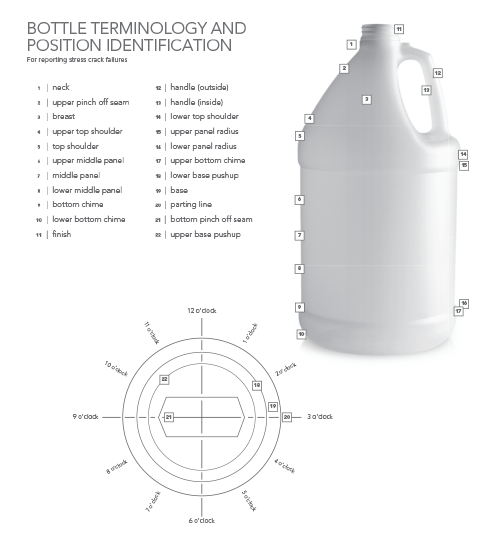

Take a look at the image below to match the definitions with corresponding numbers. Also, note the “clock” at the bottom of the image. Use this to report any defects to help us understand your issue and get it quickly resolved.

Feel confident knowing that we work hard to source the best packaging options from the United States and around the world. If you have any issues that need attention please give us a call and we will make it right.

TALK TO A PACKAGING CONSULTANT

Whether you’re looking for a stock package or a groundbreaking custom design, TricorBraun’s proven process will guide your packaging decisions from napkin sketch all the way to the retail shelf.